Ahead of the Curve on Extreme Stress

Ahead of the Curve on Extreme Stress Heading link

Studies of high-pressure material behavior typically need to strike a balance between accessing the most extreme conditions and precise control of conditions, a choice that often limitsl the ability to investigate how materials deform when sheared and to find new materials with useful applications. A new study led by CDAC Academic Partner Susannah Dorfman at Michigan State University demonstrates a method for tuning the degree to which a sample is subjected to shear stresses while under simultaneous applied pressure.

The method is based on using a two-layered sample, similar to the bimetallic strip in a mechanical thermostat. When the two attached layers have different physical properties, they will expand or contract to different degrees when the temperature changes, causing the layers to bend together. A thin film (up to several hundred nanometers thick) sample in contact with a thicker substrate can curve enough to result in gigapascals of stress.

In a previous published work [Journal of Applied Physics 125, 245904 (2019)] graduate student Eric Straley in Dr. Jason Nicholas’ lab at MSU made thin film bilayers using pulsed laser deposition. Results from this work showed that the stress in the film determined by fluorescence spectroscopy was consistent with independent measurement of bending stress, and that a ruby film on a cubic zirconia substrate with contrasting physical properties retains ~1 GPa stress at standard temperature and pressure.

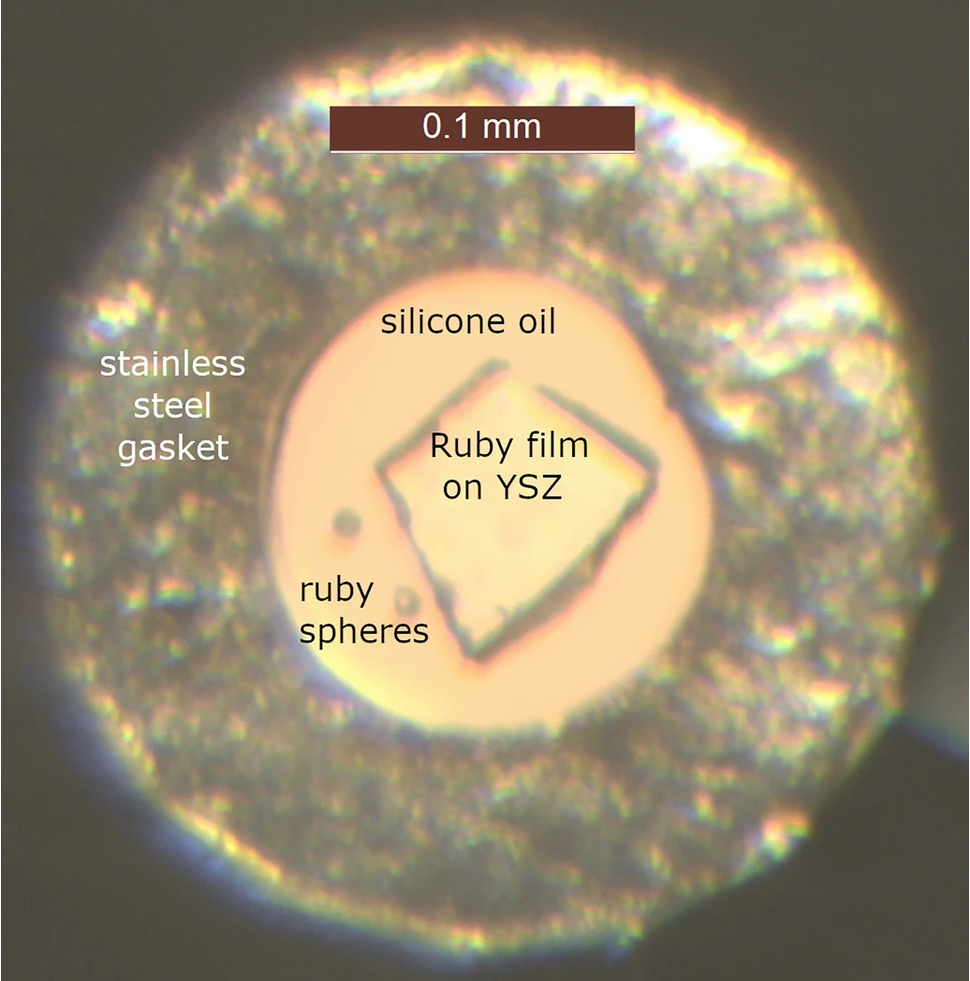

The new study combines these thin film bilayers with the diamond anvil cell, which can generate the highest static stresses possible in a laboratory setting. Again leveraging the strong fluorescence of ruby that is responsible for its characteristic red color, the variation in stress in the thin ruby film is measured as a function of additional confining stress. Measured stresses in a ruby film on a cubic zirconia substrate under compression (Fig. 1) continued to be significantly higher than a ruby on sapphire control sample due to bending of the bilayer. Differences in compressibility between the two layers also generated increasing amounts of bending stress in the sample, reaching as much as ~4 GPa when the confining pressure was 10 GPa.

The thin film combined with the diamond anvil cell method retains the advantages of the diamond anvil cell technique, including optical access to measurements and potential to reach hundreds of GPa pressures (millions of atmospheres), applicable to planetary cores and large explosive impacts. Future work using different materials may continue to tune stresses and useful properties in thin films over a wide range of conditions.

Co-author and former CDAC graduate student Ben Brugman is now a postdoctoral researcher at Arizona State University; Mingda Lv is now a postdoctoral researcher at HPCAT, and Samantha Theuer and Bella Arroyo were undergraduate participants in Professor Dorfman’s laboratory when this work was carried out.

Dorfman, S. M., S. Najiba, B. Arroyo, S. Theuer, M. Lv and B. L. Brugman, Control of deviatoric stress in the diamond anvil cell through thermal expansion mismatch in thin films. Physics and Chemistry of Minerals 49, 16 (2022).